Maximizing the Value of Best Electrical Distribution Systems with Effective After Sales Support and Maintenance Cost Strategies

In today's increasingly interconnected world, the efficiency and reliability of Electrical Distribution Systems are paramount for both industrial and commercial applications. As businesses seek to enhance their operational capabilities, the implementation of effective after-sales support and maintenance cost strategies becomes essential. This blog will explore the critical importance of industry import and export certifications in ensuring the reliability and safety of Electrical Distribution Systems, while also providing a comprehensive guide to maximizing their value. By adopting best practices in after-sales service and understanding how to navigate the complexities of certification requirements, organizations can significantly improve performance and reduce long-term costs. Join us as we delve into actionable insights that will empower businesses to thrive in a competitive landscape.

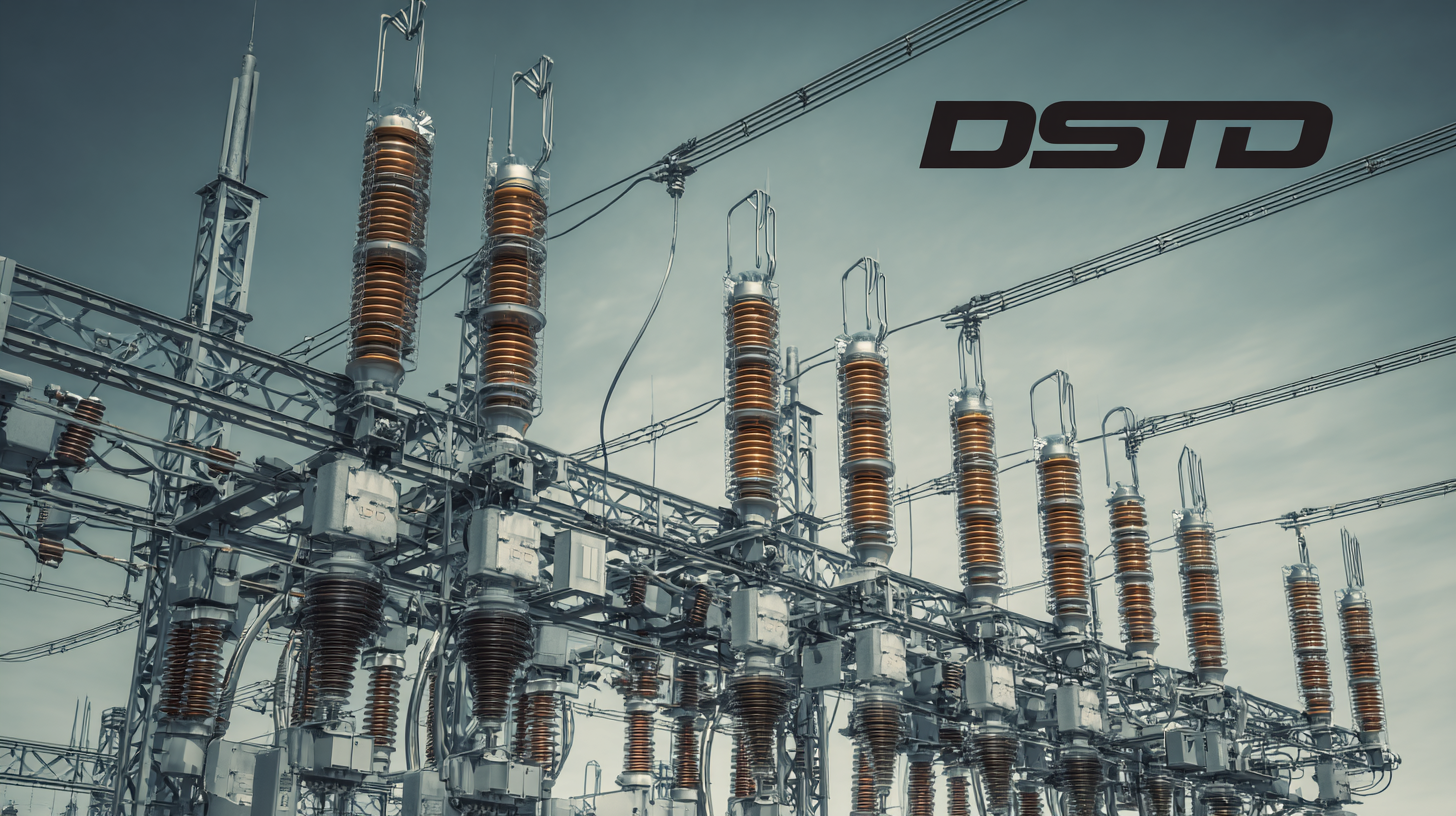

Understanding Electrical Distribution Systems: Key Components and Functions

Electrical distribution systems play a pivotal role in delivering electricity from substations to consumers. Understanding their key components—such as transformers, circuit breakers, and distribution panels—enables businesses to optimize their energy management strategies.

Transformers step down high voltage electricity for safe use, while circuit breakers protect the system from overloads by interrupting the current flow. Distribution panels then allocate electricity to various circuits within a facility, ensuring efficient energy use.

When managing electrical distribution systems, it’s crucial to implement effective after-sales support to sustain system performance. Regular maintenance helps identify potential issues before they escalate into costly repairs. One tip is to schedule routine inspections to ensure all components are functioning correctly, which can significantly extend the lifespan of your systems.

Additionally, developing a cost-effective maintenance strategy can lead to significant savings. Consider investing in predictive maintenance technologies that utilize data analytics to forecast potential failures. By addressing issues proactively, businesses can minimize downtime and enhance the reliability of their electrical distribution systems, ensuring seamless operation and optimal energy usage.

The Importance of After Sales Support in Maximizing System Performance

After sales support is a crucial component in maximizing the performance of electrical distribution systems. According to a report by MarketsandMarkets, the after sales service market for electrical equipment is projected to grow at a CAGR of 10.2% between 2021 and 2026, underscoring the increasing recognition of its importance. Effective after sales support not only ensures that systems operate at optimal levels but also prolongs the lifespan of the equipment. When companies invest in robust support services, they can achieve up to a 25% increase in system reliability, leading to enhanced overall performance.

Furthermore, maintenance cost strategies play a vital role in the financial health of electrical distribution systems. A study by the International Energy Agency reveals that proactive maintenance can reduce unexpected equipment failures by up to 70%. This reduction not only minimizes downtime but also significantly cuts repair costs. By implementing a tailored maintenance strategy, businesses can allocate resources efficiently, ensuring that both operational and maintenance costs remain within budget while maximizing the effectiveness of their electrical systems. The interplay between effective after sales support and targeted maintenance strategies ultimately determines the success of electrical distribution systems in today's competitive market.

Maximizing the Value of Electrical Distribution Systems

Cost-Effective Maintenance Strategies for Electrical Distribution Systems

Effective maintenance strategies for electrical distribution systems are crucial in maximizing their lifespan and ensuring consistent performance. According to a report by the International Energy Agency (IEA), up to 80% of electrical system failures can be traced back to inadequate maintenance practices. This highlights the need for organizations to adopt cost-effective maintenance strategies that not only enhance reliability but also minimize overall expenses.

One of the most effective approaches is implementing a condition-based maintenance (CBM) system. A study by the Electric Power Research Institute (EPRI) found that CBM can reduce maintenance costs by 25 to 30% compared to traditional time-based maintenance approaches. This is achieved by using real-time data analytics to monitor the health of distribution assets, allowing for maintenance activities to be performed only when necessary. Additionally, investing in training programs for technicians can further bolster maintenance efficiency and safety, resulting in long-term savings.

Furthermore, predictive maintenance, fueled by advancements in IoT and machine learning, is gaining traction in the electrical distribution sector. Research from McKinsey & Company indicates that predictive maintenance can reduce unscheduled downtime by up to 50%, significantly improving service reliability. As the industry shifts towards more sustainable and efficient operations, adopting these innovative maintenance strategies is imperative for stakeholders aiming to protect their investments while enhancing the overall performance of electrical distribution systems.

Leveraging Technology for Improved After Sales Support and Maintenance

In today's competitive market, leveraging technology is crucial for enhancing after sales support and maintenance in electrical distribution systems. By integrating advanced software solutions and data analytics, companies can monitor system performance in real-time. This proactive approach not only aids in anticipating issues before they escalate but also improves the overall efficiency of maintenance operations.

Tip: Implement predictive maintenance tools to analyze usage patterns and identify potential failures. This allows for timely interventions and minimizes downtime, ultimately leading to cost savings and increased customer satisfaction.

Furthermore, utilizing mobile applications and cloud-based platforms enhances communication between service teams and customers. Accessibility to vital information enables faster response times and informed decision-making. This transparency builds trust and fosters long-term relationships with clients.

Tip: Train your support staff to utilize these technological tools effectively. Regular workshops can help them stay updated on the latest features and best practices, ensuring a seamless customer experience.

Measuring the Impact of Efficient Strategies on Overall System Value

Efficient after-sales support and maintenance strategies are pivotal in maximizing the value of electrical distribution systems. According to a report by the International Energy Agency (IEA), companies with structured maintenance programs can increase the lifespan of their distribution equipment by 20-30%. This not only enhances system reliability but also results in significant cost savings. Moreover, effective after-sales support leads to improved customer satisfaction, with 73% of businesses reporting that proactive communication has a direct impact on their service quality.

Tip: Regularly review your maintenance schedules to identify and address potential issues before they escalate. Implementing predictive maintenance, powered by IoT technology, can help detect anomalies early and optimize service efficiency.

The impact of efficient maintenance strategies extends beyond just cost savings. Research from the World Economic Forum indicates that organizations that invest in robust after-sales support see a 25% increase in overall system value. This enhancement stems from reduced downtime and superior operational performance. By aligning maintenance efforts with the latest technological advancements, companies can ensure a seamless energy distribution process that supports both sustainability and profitability.

Tip: Consider adopting a data-driven approach to optimize inventory management for spare parts. This ensures that necessary components are always readily available, minimizing service interruptions and supporting continuous system performance.